Six Sigma is a rigorous and systematic methodology that uses information and statistical analysis to provide organisations with the tools to improve the capability of their business processes. The resulting increase in performance and decrease in variability, defects and waste leads to defect reduction and a vast improvement in profits, employee morale, quality of product and customer loyalty.

The following was said of Bill Smith, regarded as the father of Six Sigma, by his daughter Marjorie Hook, "Not surprisingly, the man behind the methodology was a passionate visionary and a great communicator. Bill Smith was also a perfectionist, even at home. "But not in an annoying way," Hook said. "He just did everything the right way because that was the way to do it."

Most recently we have seen an upsurge in the interest in Six Sigma. Most people who call on Six Sigma practitioners want to know exactly how Six Sigma fits in and whether they can be sure that Six Sigma will drive and deliver the improvements promised by the practitioners.

It depends

As is typical with a Black Belt response, one needs to say 'it depends'. It might appear as if this is an equivocal response, typical of all consultants. However, there are many factors that impact on the success of a Six Sigma implementation program in any organisation, the myths and the realities are described as follows.

Myth 1: Six Sigma is a quality management initiative

The first myth, that appears to be taking hold in South Africa is that this is a quality management initiative and we can simply add Six Sigma to the quality managers list of 'Things to do'. Six Sigma is different to TQM in so many aspects (though the gap is closing with the new ISO certification requirements). With Six Sigma we have dedicated project teams with pre-defined deliverables that are clearly linked to the Annual Operating Plan or STRAP. There is a high level of involvement from everybody within the organisation and there is a high degree of expectation and focus on RESULTS.

Six Sigma is a separate corporate strategic initiative and needs to be seen as a 'change management' initiative. Why 'change management'? This is because for Six Sigma to succeed it needs to become part of the corporate culture; 'the way that things are done here'.

A full-blown Six Sigma implementation has techno-structural and human impact. Typically management information systems are impacted, in addition many individuals are affected by Six Sigma especially the Black Belts and Master Black Belts. These individuals are taken out of their current role and assigned full time to mentoring projects and training individuals in the company. This in itself poses an HR problem because unless managed well, individuals who can fill these roles are typically the driven, highly motivated people in companies and 'holes' will be left when they vacate their current position.

Six Sigma Green Belt: an individual with basic training in Six Sigma principles

Six Sigma Black Belt: an individual with advanced Six Sigma training and significant personal targets of up to $1 million improvement to the bottom line within two years. This is a full time position in a company with responsibility for Green Belt training and certification.

Master Black Belt: an individual with extended advanced training, a full time position with responsibility for mentoring Six Sigma Black Belts.

Companies tend to perceive this as a major obstacle, whereas in the author's experience it is a major opportunity. The organisation soon adjusts and at a much higher performance level, this is the Hawthorne Effect in action. In the first place we have focus provided by the Black Belts while we have created opportunities for other individuals to reach their full potential by filling the gaps left by the previous incumbents.

Myth 2: Six Sigma can replace current systems

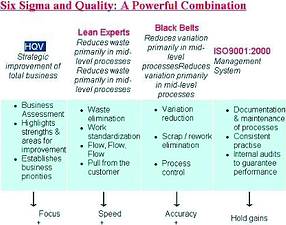

The second myth is that Six Sigma can replace current systems. Six Sigma is NOT a standalone initiative and it is NOT a replacement for the existing quality management system. Companies that have no vision or strategy will likely only enjoy short-term benefits, buying time to their ultimate demise. Six Sigma should always be accompanied by an understanding and application of LEAN principles. Too often people focus on trying to get more out of their employees while in actual fact close to 80% of the time in any process is due to standing or transportation while just less than 20% is non value added, yes this means that less than 2% of our time is spent on value added activities. Six Sigma is used to reduce waste introduced by variation and most importantly allows users to accurately predict the outcomes of actions taken. The quality management system is used to document and provides an audit trail of the changes as Six Sigma is prescriptive.

Myth 3: Six Sigma is manufacturing orientated

Another myth is that Six Sigma is manufacturing oriented. In fact, the majority of benefits currently accruing due to Six Sigma implementation is in the services sector. The tools and methodologies are as appropriate in a marketing environment as in a large steel mill. Design of Experiment is to a Steel Mill as Conjoint Analysis is to a Marketing company. What must be said is that the tools might not all be used but the methodology most definitely is common.

Myth 4: All processes must be at Six Sigma to be a Six Sigma organisation

The myth that one must have all processes at Six Sigma to be a Six Sigma organisation is also totally incorrect, there are some processes that can run at well below Six Sigma, a Six Sigma organisation knows exactly what sigma level is required to meet the customers expectations in the long term.

Myth 5: Six Sigma requires us to become statisticians

The last myth I wish to dispel is that Six Sigma requires us all to become statisticians; nothing can be farther from the truth. In no way does this statement down play the importance of statistics, however, in most Green Belt projects the teams will be the primary contributors in terms of qualifying the critical process variables. The Green Belt teams will use tools that are in common use; such as cause and effect, process mapping, quality function deployment, and apply the easily understood statistical concepts such as control charts. While any complex statistical analysis is done by designated Black Belts or Master Black Belts, to Quantify the impact of the inputs on the process. The tedium of the mathematics these days is taken care of by excellent user-friendly statistical packages such as MiniTab.

Three reality checks

The first reality check then is just how committed are the senior executives to Six Sigma, the executive team has to commit the same resources and energy driving a Six Sigma initiative as they would any other change management initiative. There is a contradictory nature to Six Sigma, while it requires change management, in itself it is an excellent tool for driving change management initiatives. Many change initiatives fail, not because employees do not share in the desire for or commitment to the change, but because they are not provided with the tools or skills in order to effect the changes required, Six Sigma provides these.

The second reality check is that Six Sigma is three things:

* Measurement.

* Methodology.

* Philosophy.

This means that it would be courting disaster to leave a Six Sigma initiative to a person or company that is only skilled in the technical aspects of Six Sigma. The service provider must have programs that will encompass sensitising management to the vital role they play, and must have tools for assessing the company's preparedness. In the author's experience the greatest risk to a Six Sigma implementation is failure to ensure management commitment. Managers need training as they are the source of project ideas and they are the ultimate beneficiaries of the projects. Management is responsible for the success of Six Sigma teams, they have to provide the environment that is conducive for the employees to succeed, ie make time and resources available.

The third reality check is that to be a truly successful Six Sigma organisation we need to tolerate failure. However, failure of projects because of lack of time or resources is NOT tolerated. Tolerable failures come about during the course of a project, events such as the initial or underlying assumptions being proven incorrect once the team has gathered data, or environmental change that makes the project outputs defunct.

The Six Sigma process will deliver benefits in any size company, and is applicable to a wide range of industries and to governmental and non-profit organisations. As with any initiative it is attention to detail in the upfront planning and careful nurturing of the teams during the implementation phase that will improve the chances of success.

For more information contact Zane van der Nest, Honeywell Southern Africa, 011 695 8067.

© Technews Publishing (Pty) Ltd. | All Rights Reserved.