Large open space (LOS) protection is traditionally a very challenging issue. Some of these challenges are: the distance from a potential fire hazard to the detection points; smoke being quickly diluted in a sheer volume of space; and a large number of occupants need to be evacuated.

The fire protection industry has been searching for optimal solutions to adequately meet building and life safety design objectives. Standards such as NFPA92B[1] have been developed and adopted specifically for LOS applications. However, many LOS applications are usually part of a landmark building involving extensive innovative design ideas to accomplish visual, energy sustainability and useability goals. These unique features have not been exhaustively considered in the existing codes and standards.

A fair percentage of commercial/non-commercial buildings exhibit the characteristics of a LOS application. These include atria in office buildings/serviced apartments, hotels, convention and exhibition centres, museums and public libraries, main railway and airports terminals, sport stadiums, halls (universities, churches, etc), entertainment and in-door recreation facilities, large warehouse type structures such as aircraft hangars, hardware/furniture stores, shopping malls, arcades, industrial sites and so on.

When considering the best fire protection solution for such building types, the following aspects must be taken into consideration:

* The key attributes of the building layout (ie, ceiling height and interface to outside ambient environment).

* Ventilation (ie, natural or mechanical).

* Airflow dynamics (ie, building leakage, air supply and return vents and air handling unit (AHU) operation).

Examples of the impact on fire growth and smoke propagation are the possibility of stratification, the extent of smoke dilution and uncertainty of a smoke plume forming.

Beam detectors have often been used in LOS environments such as warehouse applications mainly due to the fact that many other conventional spot detectors such as ionisation or photoelectric type are not sensitive enough when mounted at a usually very high ceiling level. Not to mention the maintenance of conventional spot detectors is quite difficult when mounted at such high ceiling levels. Over the years, recommendations for beam detectors design and installation have been changed to reflect the need for detailed design considerations in order to achieve the level of protection required. As stipulated in BS5839-1:2002 revision[2], additional considerations include smoke plume forming, the need to provide ceiling level detection, etc. This highlights two important issues in regards to the effectiveness of LOS protection using beam detectors. The first issue is how to position the beam detectors when close spacing is required for supplementary detection of a rising smoke plume according to BS5839-1:2002 revision[2]. The second is how to assess the system design so different fire scenarios, hazards and locations can be covered.

Today, performance-based building code has been in use in many countries such as Australia and USA. It provides great incentives for safer and more innovative building designs as well as encourages the application of advanced technology. In contrast to the prescriptive 'deemed-to-satisfy' (DTS) approach, the cost of the solution is optimised when the building safety margin is maintained or even enhanced.

Because of the new performance-based approach, many computer tools have been developed so a fire safety system design can be validated. FDS is one of the leading CFD models, which was developed by the Building and Fire Research Laboratory, NIST [3]. This model has been used extensively for the purpose of fire and smoke growth, flame spread, tenability conditions and structural integrity[4]. As apart of the transition from prescriptive to performance-based designs, it becomes a necessity to be able to quantify the performance of the system in order to assess against set of design criteria.

For the past number of years, very high sensitivity air sampling-type fire detector has been proven to be a fit-for-purpose solution for LOS applications. This is due to a number of key attributes of the technology such as highly sensitive and cumulative sampling, and ease of maintenance.

However, there is still a need to be able to model smoke detection performance using CFD so fire engineering objectives can be assessed. The following sections give a summary of how FDS and other CFD-based computer models can be applied to quantify the performance of ASD in terms of response time in different fire scenarios for LOS applications. Just like any other computer model, a systematic validation is needed, especially when there is lack of information in such area. This process involves the design of the fire safety system, validation, in-situ hot smoke tests and verification.

Quantitative assessment of ASD performance

Traditionally, a simple calculation is applied to assess the performance of a spot type smoke detector in terms of activation time. Fire dynamics simulator (FDS) may be used to evaluate smoke obscuration level after the fire is fully developed so the tenability can be taken into consideration. There is very little research conducted on the topic of how a computational simulation model is used to calculate smoke propagation at its early development stage. This is becoming an important topic in performance-based design where early and reliable fire detection is paramount to facilitate orderly and safe evacuation and prevent asset losses.

Very high sensitivity air sampling-type detector (ASD) and smoke cumulative effect have not been modelled and usually are not well understood. To optimise the location of ASD detectors and their sampling points for early fire detection, a set of computer simulations can be carried out using FDS which calculates smoke movement in the LOS, smoke detection performance and the overall protection in accordance with performance-based fire safety system design methodologies.

ASD system design

For an ASD system, the smoke obscuration level measured in a detector's chamber is a function of the smoke concentrations from a number of sampling holes, flow rates and transport time within the ASD pipe network. The flow rate and transport time from each sampling hole can be calculated by a CFD software named ASPIRE, developed by Vision Fire & Security[5]. The smoke concentration profile at any given time at each sampling point is obtained from FDS fire model. Hence, the smoke obscuration for an ASD system can be calculated.

The ASD detector response time is then derived comparing the calculated smoke obscuration level with a predefined fire alarm level. Because ASD is an 'active' type smoke detection technology, issues associated with the conventional spot detectors such as 'smoke entry lag time' and airflow effect are irrelevant. This in turn enhances significantly the accuracy of computer model prediction.

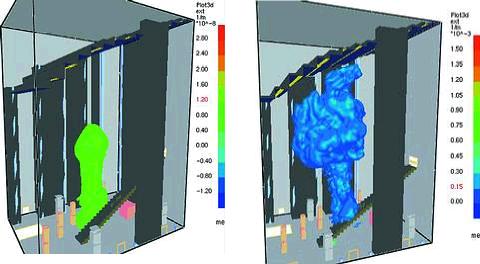

Figure 1 shows an example of a fire at different development stages in a large atrium.

FDS validation of smoke development and measurement

FDS has been through extensive validation in fire engineering on modelling heat transfer, gas movement and combustion phenomena, etc[4][6]. It has also been used widely to assess untenable conditions such as the upper hot layer temperature and visibility in a fire scenario. However, there is no report so far on evaluating the performance of a smoke detection system via FDS simulation directly. Therefore, it is necessary to validate FDS simulation by a series of real fire/smoke tests before any serious application.

A series of fire and smoke tests and simulations were carried out on ASD products for validation purposes. The fuel materials tested include liquid (ie, Heptane) and solid (ie, timber and paper). The enclosure sizes involved in the tests vary from about 80 m2 with a ceiling of height 3,6 m (ie, similar size to a standard test room specified by UL 268 standard[7]) to over 550 m2 with a ceiling height of 8 m in a real warehouse. In order to model the early and very early detection ability that the ASD system possesses, some very small fire sizes were investigated in these environments. The minimum fire size tested and simulated is as low as a few hundred watts.

The model validation can be summarised as follows:

(1) FDS is capable of simulating selected fuel materials and small fire sizes.

(2) To evaluate ASD system performance, FDS simulation results can be combined with other CFD models to calculate the ASD response time. The accuracy of simulation and test results was to industrial accepted standard.

(3) Further investigation of large fire sizes in LOS environments is recommended.

In situ smoke tests and verification

The in situ tests may involve a number of preliminary 'mock-up' tests and a final formal fire test. One of the test methods commonly used is the Hot Smoke Test procedure detailed in Australian Standard AS 4391-1999[8]. The fire source consists of six A1 size fuel trays containing denatured industrial grade methylated spirit (Grade 95). The fuel trays were placed in a metal rig.

Since the selected fuel results in a clean combustion without visible smoke, an external smoke source is necessary to generate sufficient smoke in order to simulate a large ultra fast growth fire, commonly used for large open space fire system assessment.

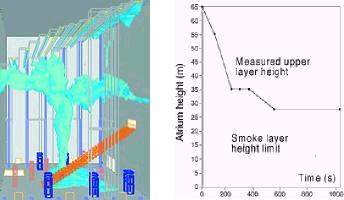

A comparison of the upper hot layer height from the simulation and one actual testing for a 2 MW liquid fire is illustrated in Figure 2. It can be seen that the simulation result also agrees very well with the in situ test measurements.

Conclusions

There are many aspects of fire safety system design for large open space buildings. The fire detection system is one of the most important elements. Reliable and early detection ensures life safety and minimises damage to building and assets, therefore maintaining business continuity.

After extensive application-based research, testing, verification and validation, it has been proven that air sampling-type detector very early warning fire detection system is a fit-for-purpose solution for large open spaces protection. CFD model can be applied to aid and verify system design to achieve an optimal protection level with value-added features. It is concluded that:

* FDS is capable of simulating smoke propagation and concentration in a wide range of enclosures. Simulated smoke properties have similar acceptable accuracy to other thermal dynamic properties such as heat and temperature.

* Combined with ASPIRE pipework design and modelling software, in conjunction with authors developed computation and integration method, FDS can be used to evaluate the detection performance of the ASD system. The simulated ASD system response time, agree with in situ tests even in an extremely high ceiling, large open space environment.

* Another important smoke property, hot layer height prediction, matches very closely with the test results as well. It is a challenge to use other detection technologies such as beam detectors when the hot layer height varies and the forming of the smoke plume is uncertain as this may require supplementary detection involving close spacing and different layers of beam detectors.

* The simulation results agree with the ASD detection performance assessment. According to the FDS simulation results using a fire growth trend up to 5 MW, the proposed ASD pipe network layout adequately provides early warning protection to meet the overall fire safety system design objectives.

* It has been demonstrated that a certain percentage of smoke, after the fire size reaches a certain level, will get to the ceiling level even in the presence of temperature gradient. The investigated upper hot layer temperature gradient condition has a minor stratification effect on the studied fire growth rates. It highlights the fact that very high sensitivity ASD detectors are suitable for all assessed stratification scenarios.

References

[1] NFPA 92B, Guide for Smoke management Systems in Malls, Atria, and Large Areas, 2000 Edition, NFPA.

[2] BS 5839-1:2002, Fire Detection and Fire Alarm Systems for Buildings - Part 1: Code of Practice for System Design, Installation, Commissioning and Maintenance, British Standards.

[3] K.B. McGrattan, G.P. Forney, and K. Prasad, Fire Dynamics Simulator (Version 3) - User's Guide, NISTIR 6784, 2002 Ed.

[4] S. Hostikka and K.B. McGrattan, Large Eddy Simulation of Wood Combustion, Interflam 2001, pp775-765.

[5] ASPIRE( Pipework Modelling Program version 3.09.10, Vision Systems Ltd, 2002.

[6] D.D. Evans, Use of Fire Simulation in Fire Safety Engineering and Fire Investigation, UJNR. Fire Research and Safety. 15th Joint Panel Meeting. Volume 2, Proceedings. March 1-7, 2000.

[7] UL 268 2002 Standard for Smoke Detectors for Fire Alarm Signalling Systems.

[8] AS 4391-1999, Smoke Management Systems - Hot Smoke Test, Australian Standard, 1999.

© Technews Publishing (Pty) Ltd. | All Rights Reserved.