As a signatory country to the worldwide ISO standards, the South African fire detection industry should take interest in the publication and adoption of EN54-20 'Fire detection and fire alarm systems – Part 20: aspirating smoke detectors' by European signatory countries.

As local awareness of aspirating technology improves, this standard will go a long way to ensure the distinction between reputable products and those that are either unapproved or inappropriate for the intended applications.

Reference to www.EN54-20.org outlines the important points to consider when establishing the implications such a standard would have on the local fire detection industry.

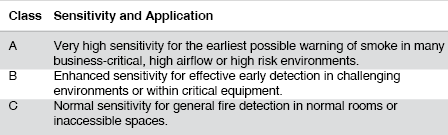

For instance, a classification system has been introduced enabling identification of the most appropriate sensitivity of an aspirating smoke detector for an application:

This sensitivity classification system employs test fires of differing smoke dilution and fuel to fire test the product. Essentially, Class C test fires are used to demonstrate normal sensitivities, ie, sensitivities similar to optical point type smoke detectors. For Class A and Class B testing, fires with reduced fuel content and increased smoke dilution are employed to establish high or enhanced sensitivity.

Integrity of airflow through the sampling pipe network is also specifically addressed with a requirement of ±20% change to indicate airflow fault. Although this may create some engineering challenges for some manufacturers, it would ultimately lend itself to greater reliability.

The standard also addresses the pass criteria for the smoke tests by way of a defined 'End of Test' or EoT. This addresses the inherent transport time delay an aspirating system has.

Sure, the detector may detect smoke, but if a system only responds after a conventional type detector and after the test fire has finished, it provides little benefit and makes a mockery of any minimum standard and aspirating technology as a whole. EN54-20 addresses this and it is incorporated into the classification system.

What should be considered here is that the classification system is not a system identifying products of differing qualities, it does not extend so far as to recognise product features such as alarm thresholds, ease of use, maintenance, etc. As www.EN54-20.org points out, the system makes no differentiation between, say, a detector with 30 holes (Class A) versus a detector with only 3 Class A holes – “The stark difference in area coverage is also reflected in the detector’s ability to provide the earliest possible warning of smoke…” so the risk would be that, without disclosure of the number of holes supported, a detector with fairly low sensitivity could be marketed as performing at a higher sensitivity classification than it realistically can.

The classification is rather a reference to detector sensitivity and assists with decision making in terms of applicable technology. The standard would not be used to compare one product to another. What it would go a long way to achieving, particularly in RSA, is empowering professionals to identify sensitivity and capability of a system they choose to use.

What is ASD?

An aspirating smoke detector is a smoke detector which provides protection by drawing air into a detector unit. This is done via a network of sampling pipes and capillaries where sampled air is passed through the system and analysed for the presence of combustion products.

Aspirating systems usually draw sampled air from multiple holes spaced around a protected area – the cumulative effect of smoke entering more than one hole results in the system being more responsive than smoke entering only one sampling point.

The detection element inside these devices is often based on laser technology using the optical scatter principle. Other methods include cloud chambers and even embedded optical point type smoke detectors.

Aspirating detectors are traditionally used for applications where early warning of fire is paramount and protection of assets is key. These include business-critical computer servers or telecoms installations where business continuity cannot be jeopardised. Other applications include where building aesthetics are a priority or challenging environments for maintenance or where high airflows are present.

For more information contact Patrick Denyssen, Xtralis, +27 (0)82 906 0219, [email protected], www.xtralis.com, www.vesda.com

© Technews Publishing (Pty) Ltd. | All Rights Reserved.