When environmental conditions are made challenging due to extreme temperature or poor air quality, early fire detection systems are specifically engineered to compensate for these factors and deliver reliable smoke detection.

Facilities such as mines, power stations, manufacturing operations, hazardous areas and cold storage areas all place extraordinary demands on fire detection systems, by virtue of the high volume of dust particles in the air; and the presence of corrosive materials and temperatures outside the normal range of ambient air.

Vesda systems can also discriminate between smoke and sources of nuisance alarms therefore the frequency of false alarms due to dust, or other airborne particles is reduced.

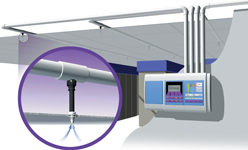

A Vesda air sampling smoke detection system uses a pipe network to draw air samples through a dual-filtration system back to a detector in a remote, clean location. The pipe network is simply PVC pipe (in extreme scenarios ABS pipes are recommended) with holes drilled where sampling points are required.

The first stage removes dust and dirt from the air sample and warms or cools it, before allowing the sample to enter the laser detection chamber for smoke detection. The second (ultra fine) stage provides an additional clean air supply, to keep the optical surfaces within the detector clear from contamination; and to ensure the stable calibration and long life of the detector.

The air sample is passed through to the calibrated detection chamber, where it is exposed to a stable controlled laser light source. When smoke is present, light is scattered within the detection chamber and is instantly identified by the highly sensitive receiver system.

For more information contact Brett Birch, African Region leader, GE Industrial, Security, +27 (0)21 937 6000, [email protected]

© Technews Publishing (Pty) Ltd. | All Rights Reserved.