It makes economic sense to utilise the talents of fire team members wherever possible. Training exposes them to a broad fire safety base. They therefore know more about fire than any other employee.

An example of how their knowledge could be usefully employed, would be in the monitoring of the ubiquitous fire door. Let fire teams evaluate and inspect the doors regularly.

This not only helps ensure that the doors will function effectively but also familiarises the team with fire resistant construction that will prevent fire spread. Knowing where fire can penetrate to adjoining areas is very useful. Both in evaluating the risk and during fire-fighting.

Fire-doors will be found protecting openings in fire resistant walls which:

* Enclose ducts, chutes or emergency stairs or routes.

* Separate areas of different usage such as production and storage.

* Isolate high value equipment such as computer suites or high risk processes like spray painting operations.

* Sub-divide areas of the same or similar risk to limit fire spread and size.

The suitability of the doors used should be equal to the fire resistance requirement of the separation wall in which they are mounted.

Fire doors

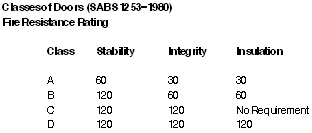

A fire door assembly usually consists of both door and frame or supporting rails and varies from single or double-leaf hinged to horizontal or vertical sliding types. Based on fire performance, four classes of doors are available. The stability, integrity and insulation ratings vary according to the class of door as shown in the Classes of Doors table.

Notes to the table

Under fire test conditions:

Stability means that no part will collapse or burn away. Integrity means that the unexposed part of the door should not crack to allow hot gasses to ignite combustibles on this side. Insulation means that the temperature of the unexposed face will not rise above 160°C.

It is important to appreciate that hardware such as locks, latches, self and automatic closing devices should be approved and be compatible with the class of door, ie, have the same fire resistance.

Metal identification plates bearing the manufacturer's name, serial number, date of manufacture and class of door should be fixed to both the door and where applicable, the frame.

Inspection

Inspection and maintenance should be carried out at least every six months or more frequently where necessary. Checks to ensure that nothing obstructs the correct operation of the door should also be included in more regular routine monitoring.

Items to be checked will depend on the manufacturer's recommendations but will inevitably include:

* Hardware such as locks, latches, self or automatic closing devices to ensure they are approved and are compatible with the door.

* Doors not held open by wedges or hooks.

* Doors open and close easily and fully.

* No signs of corrosion or damage.

* Moving parts and fusible links or detection devices not painted.

* Check hinges and guides for wear and lubricate where necessary.

* Travel paths of all moving parts free from obstruction.

* Doors clearly marked and accompanied by special instructions where necessary.

* Floor areas marked as no stacking areas.

* Combustible stock kept clear of doors. Most doors have a reduced insulation property. Some may have none. Conduction of heat could then be a problem.

* Automatic closing devices tested for effective operation.

Inspect the wall in which the door is located for obvious defects including:

* Any openings not sealed or protected, eg holes through which pipes or cables pass.

* All openings around the perimeter and on sides and top suitably sealed.

* Walls should extend through ceilings to the roof and sometimes must extend through the roof to ensure effective separation.

Report any faults immediately and record the results of the inspection.

A door is a door, is a door and seldom gets any attention. When it has to perform properly in a fire situation, however, its importance is elevated. Seems like a good idea then, to give your fire doors a little TLC. You will certainly be grateful you did, the day you have to shut out a fire.

References:

SABS 1253 - 1980

SABS 0400 - 1990

FPAUK Fire Safety Data Sheet GP12

© Technews Publishing (Pty) Ltd. | All Rights Reserved.