Within the fire industry, detectors are categorised as early warning smoke detection (EWSD) and very early warning smoke detection (VEWSD). In fact, some people use these terms very loosely and do not differentiate the two correctly.

An EWSD system provides detection of a fire condition prior to the time that it becomes threatening to the occupants of a building or equipment within it. Generally, this is the time that smoke is visible. Let us use an example of a low voltage switch cabinet with a fault within the electronics resulting in a thermal event; it may smoulder for hours before a flame ignites. We refer to the smouldering stage as the incipient stage of a fire. During this incipient stage, the human eye will not see the particles but the human nose may smell them. EWSD are not sensitive enough to detect smoke at the incipient stage of an electrical-type fire. Only a VEWSD will detect an incipient fire and thus the term, 'very early warning'. This stage of a fire could last for hours or even days and it could cause significant damage.

Smoke contamination

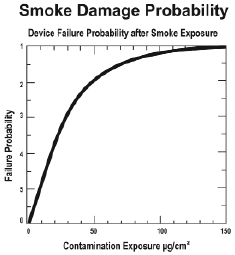

So why is the detection of smoke at the earliest possible stage important? Because the biggest risk to the continuous operation of an industrial facility is the smoke damage to electrical equipment, not the fire. In fact, according to the USA Federal Commission of Communications, 95% of all damage within telecoms facilities is non-thermal. The by-products of smoke from PVC and digital circuit boards are gases such as HCL and these gases will cause corrosion of IT equipment. Figure 1 depicts the increased risk of failure with an increase of particulate exposure. Even at 16 micrograms/cm² there is moderate corrosion with long-term effects on electronics, at 30 micrograms/cm² the corrosion is active and the effects are short term. Above this the damage to equipment is detrimental to ongoing performance.

Shortfalls of conventional fire detection solutions

There are several types of common smoke detection technologies often deployed to protect equipment and facilities – spot detectors, beam detectors and rate of rise heat detectors. While these technologies are adequate in some scenarios, each has a shortfall that prevents it from being appropriate for a VEWSD approach.

Point type detectors, are one of the most common types of smoke detectors used today. Point detectors are 'passive' in that they wait for smoke to enter a detection chamber where an optical sensor identifies the presence of smoke. A key problem with point detectors is that dust, insects and other airborne debris can impede the flow of air and smoke into the detection chamber. This can lower sensitivity and also cause them to become prone to nuisance or false alarms in some environments.

Beam detectors monitor a beam of light between two elements to detect the presence of smoke. When a significant level of smoke disrupts the beam, an alarm is activated. Unfortunately, beam detectors are prone to nuisance alarms from obstructions or building movement. These false alarms reduce confidence in the effectiveness of beam detectors and often lead to disablement. In addition, beam detectors require regular cleaning and maintenance of reflectors and beams surfaces due to dirt and contaminants in the air.

As indicated by their name, rate of rise heat detectors measure the rapid rise of ambient room temperature to identify the imminent threat of a fire. Rate of rise heat detectors are often integrated with fire suppression systems and are typically mounted on ceilings where heat from a fire collects. Unfortunately, a smouldering fire typically produces only low initial levels of heat, making these detectors ineffective for early detection.

Aspirating smoke detection solutions

A new breed of aspirating smoke detector (ASD) solutions is gaining rapid adoption within industrial facilities. ASD solutions are designed to detect the earliest presence of a fire while it is still in the first stage of development, before smoke may be visible to the human eye. The most effective ASD solutions address reliability issues found in conventional smoke detectors through an alternative approach to capturing and analysing air samples called aspiration.

Aspirating smoke detection solutions use multiple air sampling tubes, spread out across large open facilities, to capture and condition air samples. These samples may be conditioned to remove dust and other contaminants that can cause false alarms with conventional smoke detectors. Finally, air samples pass through a highly sensitive centralised laser detection unit. If the presence of smoke is detected, alarm signals are processed and transmitted to centralised monitoring stations, fire alarm panels, as well as to integrated systems such as building management, equipment control or fire suppression systems. The entire process takes only seconds.

Because aspirating detectors are actively sampling the air in a facility, they are tolerant of smoke dilution and are reliable in high airflow environments. Because they monitor the flow into the pipe network and indicate a flow fault if the flow is too high (broken/open pipe) or too low (blockage) they provide an additional layer of supervision that passive point (spot) type smoke detectors cannot provide.

Ready for extremes

Spot type smoke detectors are passive detectors in that they wait for smoke and rely on the airflow to transport the smoke to the detector. Therefore their performance is affected by high airflow. Since the rate of smoke generation in a smouldering fire is relatively small, and the airflow velocity around the equipment or in the facility may be relatively high, the movement of smoke is dominated by the airflow of the mechanical systems.

Furthermore, the smoke generated during the incipient stage is not hot therefore there is very little thermal lift. The smoke dissipates more widely and is diluted. This often prevents smoke from moving directly to the ceiling of an industrial facility, where spot type detectors might be located according to fire codes. An ASD system is active, constantly sampling the air from multiple points throughout the environment of a piece of equipment or the broader facility. It is not totally dependent on thermal energy to transport the smoke to the detector. The active nature of ASD systems overcomes the uncertainties of smoke ingress through insect screens and the other components of a spot detector that are designed to keep insects and smoke out. The passive nature of spot detectors is the cause of their reported poor response, well outside of the manufacturer’s quoted figures. It is also the principal cause of many spot detectors remaining in service despite their contamination and risk of failure in a real fire event.

The active detection method used by ASD allows the use of clever methods to keep the detector optics clean, such as the use of a clean air barrier within the laser chamber. This allows ASD to operate in harsh industrial environments with high levels of pollutants such as dust and dirt, without risk of detector contamination. ASDs are frequently used in the most harsh environments such as coalbunkers of power plants or heavy manufacturing environments. The use of a pipe network and filtration of the air sample allows contaminants such as dust and lint and even harmful gases such as HCl to be removed before being sampled at the sensitive detector.

For more information contact Lauren Sher, Xtralis, +27 (0)82 446 7602, [email protected].

© Technews Publishing (Pty) Ltd. | All Rights Reserved.