Everything from a single source or ‘best of breed’? Decision makers often find themselves confronted with this question when they have to choose between an all-inclusive, complete solution from one manufacturer and the products and services of several different providers. Heterogeneous system landscapes and the constantly increasing complexity of major projects are prompting more and more customers to long for a return to ‘manufacturer uniformity’. The driving arguments behind this trend are criteria such as high integration capability and clear responsibilities.

Standards as basis for best of breed

When assembling the components they need for a network-based video system, companies do not rely solely on a particular manufacturer in a best-of-breed approach. Instead, they put together those components which they think satisfy the performance requirements most completely. In such cases, users then expect that this combination of the best components from each of the various groups will deliver the best overall solution. Standards such as ONVIF are intended to guarantee compatibility so that this works.

Greater manufacturer uniformity, greater customer benefit

The realm of high-tech is characterised by short innovation cycles and products in which even short-term technical innovations often provide considerable benefits for the customer. It is regularly discovered that industry standards only represent the lowest common denominator: If innovations can be reflected by the specifications of the standards, it will be a simple matter to combine products from different manufacturers.

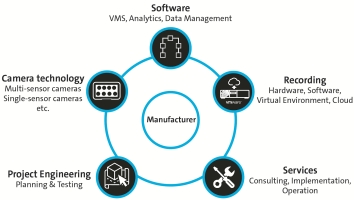

In many cases, however, new, innovative products have special functions which cannot be implemented together with systems from another provider by means of an established standard. Now if the innovative product is installed as part of a best-of-breed solution, the performance of the system as a whole is ‘choked’ and the benefit to the customer is limited. Furthermore, manufacturers are changing increasingly from suppliers of single products to total solution providers, and more often offer systems that are specially tuned to each other. And when all components from the same manufacturer are used, this frequently means that the individual technological modules (camera, recording, software platform, etc.) are completely compatible with each other, in fact they may even have been developed together.

This is important, for example, when the quality of the captured image and video data must be exactly compatible with the AI analysis system. Usability and uniformity of the user interfaces, and thus also less training expense and fewer operating errors, are another example.

Privacy by Design and Security by Design

Advocates of a uniform manufacturer approach are particularly fond of citing data protection in support of their argument: If the system components from different manufacturers do not work together perfectly, data protection requirements may possibly not be complied with. The General Data Protection Regulation (GDPR) provides for heavy fines depending on the severity of a data protection violation.

The threat of similar substantial consequences also exists with regard to data security in the case of an incorrectly understood best-of-breed approach: As networked computer systems or elements in the Internet of Things (IoT), video systems are a popular target for attack. Manufacturers counter this with interlocking functions for data protection and data security (‘Privacy by Design’ and ‘Security by Design’). In this case, more uniformity often means better integration of the security functions and therewith reduced vulnerability. It is also often advisable to think about whether a manufacturer is able to organise its research and development processes without any external financial or political pressure – technical backdoors are a real threat.

Consulting, planning and implementation from a single source

But there are important arguments in favour of the ‘single source’ approach on more than just the technical level. As soon as the requirements and objectives of a project have been defined, manufacturers can contribute valuable consulting services: By definition, they have the greatest expertise regarding their products, and they can often draw on an extensive source of experience from previously completed projects.

When it comes to the graphical planning of a solution, 3D planning teams of some manufacturers are now able to create ‘digital twins’ of even large customer environments and exactly simulate the total solution in its entirety, including cameras and other components. In such cases, important aspects such as required resolution densities, compliance, data protection or even requests to modify components can be dealt with in advance. Many installers cannot deploy the technical and human resources that are available to an established manufacturer.

Ultimately, implementation and successful operation represent the last major challenge: Many installers and integrators have a vast fund of experience which they have acquired over many solutions with various manufacturers, but they may not necessarily have access to the detailed knowledge of the manufacturer’s expert teams. Moreover, clear responsibility offers enormous advantages (‘one-face-to-the-customer’ principle) precisely in the case of larger projects with many different spheres of responsibility.

This applies in particular to support. If problems arise, they can be attributed unequivocally to one manufacturer, it is simply not possible to pass the responsibility off to another component when troubleshooting.

In addition to many functional aspects, such as the technical limitations due to industrial standards and data protection and data security considerations, it may make sense to adopt a strategy of manufacturer uniformity in terms of project management as well. However, to ensure that this does not become a gamble in itself, it is important to check the skills of the manufacturer beforehand. The manufacturer may offer customers the opportunity to visit the company’s headquarters and satisfy themselves on site, in person, that they have chosen the right partner.

| Tel: | +49 941 8700 111 |

| Email: | [email protected] |

| www: | www.dallmeier.com |

| Articles: | More information and articles about Dallmeier Electronic Southern Africa |

© Technews Publishing (Pty) Ltd. | All Rights Reserved.